Anu Sourcing can offer IP protected contract manufacturing of your products (Parts/ Components, Sub-Assemblies, Assemblies, inspected & performance tested as per your specifications / international standards).

We will work closely with you to provide strategic sourcing to cut costs. We will use key performance indicators that provide constant feedback on the performance of Supplier partners, who are supplying products to you. We will also assist/ contribute in the development and review of strategies for the commodities that we work with you.

We will conduct extensive Supplier Evaluation Audits & maintain Approved Vendor List for various commodities.

Castings

Forgings

Changes in Government’s Policies & Tax Structure, etc)

Ferrous: SG Iron & Grey Cast Iron, Carbon Steel, Alloy Steel, Stainless Steel

Non-Ferrous: Aluminium, Zinc, Magnisium, Lead, etc

- After the completion of Pattern Development and once First Sample is poured, we will collect Cast Samples, Dimensional Reports, Mechanical Properties, Chemical Composition and Microstructure reports along with Test bars for 3rd party testing.

Ferrous & Non-Ferrous, Closed & Open Die Forgings

Injection Molded & Compression Molded Components

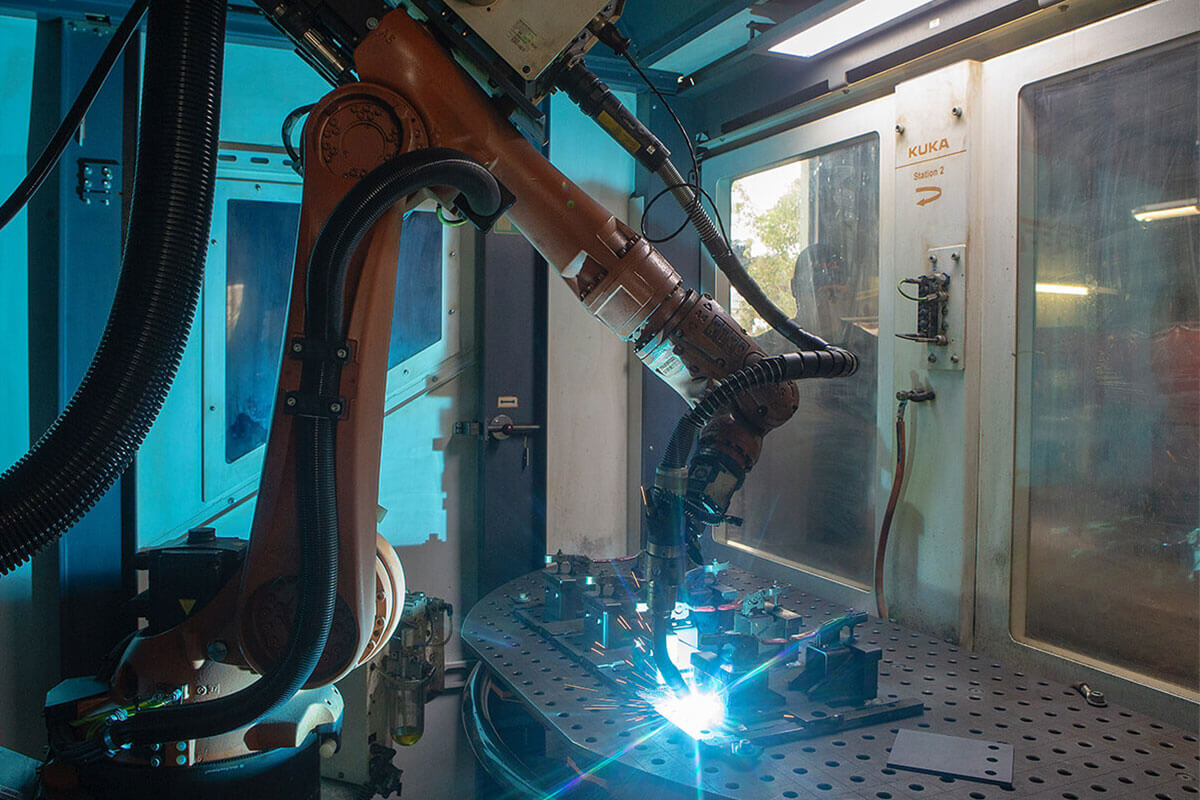

Sheet Metal Components produced using Press Tools on Power Presses & Welded Components

Sheet Metal Components produced using Press Tools on Power Presses & Welded Components